Mgo board is paving the way for a

revolution in the modular construction industry.

The raw material is the first step for guaranteeing the quality of the mgo board.

For the MgO board, the main raw materials are as follows:

Mgo powder

Mgso4

Sawdust/Bamboo

Perlite

Additives

Of these raw materials, Mgo powder can be said the most important one, because the content and the activity of the mgo powder are closely related to the mgo board quality.

We have to guarantee the content is 85%, the activity is 65%

For MgO powder, we only use the brand, which is called Huan Ling, which is in the Northeast of China.

The reason why we only use this brand is because they mainly manufacture the mgo powder, which application is to produce mgo board.

Before they deliver the Mgo powder to us, they will share the test report; after we get the mgo powder, we will also do the test on our own again.

In the process of producing Mgo board, usually, there are two times of curing.

First time curing

In the first time curing, it needs 12 hours and the temperature is around 35℃, less than 40℃.

The chemical reaction only be finished at 60% and the strength and durability can not be reached.

Second time curing

The main function of the second-time curing room is to dry the redundant water/moisture of the board.

It needs 72 hours and the temperature should be controlled to 40-50℃, less than 50℃.

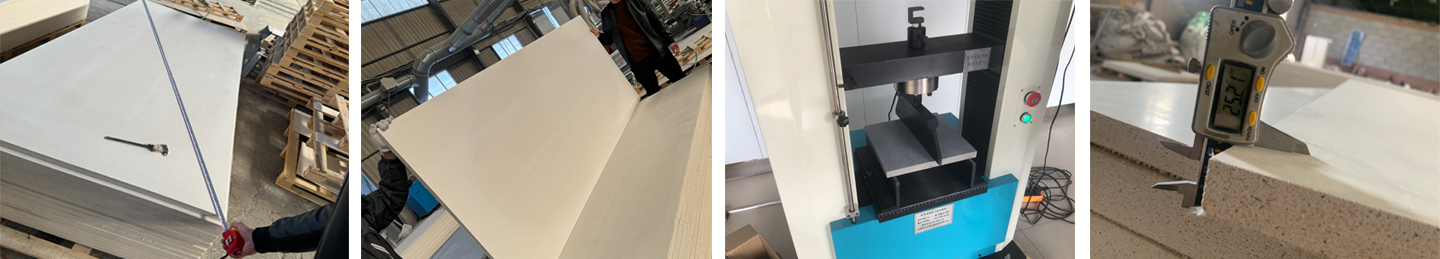

Each batch of the mgo board will need to do the inspection.

I have the inspection team, strictly do the inspection for each batch mgo board.

I had full experience in helping customers do the CE certificate, and UL certificate in the factory.

When the customers do these certificates, usually, we usually need to prepare the full detailed QC documents.

During production, workers need to follow each instruction.

Before loading, we will screw the Green color PE strip in the pallet. This way could guarantee the whole pallet is much stronger and that the pallet will not be destroyed after a long time of transportation. When customer does the unloading, sometimes the forklift destroys the PE strips. If we screw the PE strips into the wood, then this kind of problem will be avoided, which could guarantee there is no risk when customers do the unloading.

If there is some space between two pallets, we will use a Dunnage bag.

Strong wood pallets

Corner Protection & film

Use stripes to fix the containers, and guarantee the container does not move

Loading is the final step for the manufacturer, we need to 100% make sure it is safe after long-distance transportation.

HOME 丨 PRODUCTS 丨 APPLICATION 丨QC 丨 SUPERIORITY 丨ABOUT丨CONTACT

©2023 CopyRight zhengheinc.com Inc.All Rights Reserved. Email: sky@zhengheinc.com